KM Model NO. PBS-905 (S / D / T / Q / O)

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

Feature:

-

Multiple die head configuration is especially ideal for producing medium and small sized containers at high production speed. Custom machine configurations are available.

-

Also available to produce product with visi-stripe, two color and two layers.

-

10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

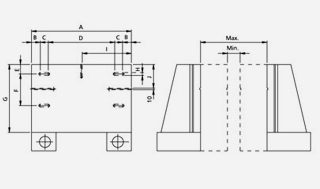

Mold Platen Dimensions

|

NO.

|

PBS-905S,D

|

PBS-905Q

|

PBS-905O

|

|

MAX.

|

640

|

500

|

420

|

|

MIN.

|

240

|

200

|

80

|

|

A

|

450

|

630

|

650

|

|

B

|

35

|

55

|

65

|

|

C

|

50

|

50

|

50

|

|

D

|

220

|

420

|

420

|

|

E

|

60

|

60

|

60

|

|

F

|

220

|

200

|

200

|

|

G

|

449

|

429

|

429

|

|

H

|

18

|

18

|

18

|

|

I

|

220

|

310

|

320

|

|

J

|

165

|

150

|

150

|

Machine Specification

|

Model No.

|

UNIT

|

PBS-905S

|

PBS-905D

|

PBS-905T

|

|

Max. product capacity

|

C.C.

|

10,000~20,000

|

1500~5,000

|

600~2,700

|

|

Min./Max. dia. of product

|

mm

|

150~300

|

80~180

|

60~140

|

|

Screw diameter

|

mm

|

90

|

90

|

90

|

|

Screw L/D ratio

|

|

24/1

|

24/1

|

24/1

|

|

Inverter motor

|

HP

|

60

|

60

|

60

|

|

Screw rotating speed

|

r.p.m.

|

15~65

|

15~65

|

15~65

|

|

Extruding capacity

|

kg/hr

|

130

|

130

|

130

|

|

Outer diameter of die mouth

|

mm

|

240

|

135

|

80

|

|

Mould center distance

|

mm

|

~

|

250

|

160

|

|

Clamping force

|

ton

|

16.8

|

16.8

|

16.8

|

|

Oil hydraulic drive motor

|

HP

|

30

|

30

|

30

|

|

Dry cycle

|

sec.

|

5.7

|

5.7

|

6.0

|

|

Pressure of air

|

Kg/cm²

|

6~8

|

6~8

|

6~8

|

|

Compressed air consumption

|

L/min

|

1,500

|

1,500

|

1,500

|

|

Total power consumption

|

kw/h

|

96.0

|

94.0

|

95.7

|

|

Machine net weight

|

kg

|

10,000

|

12,000

|

12,000

|

|

Gross weight

|

kg

|

11,500

|

13,000

|

13,000

|

|

Machine dimensions

|

m

|

5.6x4.4x3.5

|

5.1x3.1x2.9

|

5.1x3.1x2.9

|

|

Model No.

|

UNIT

|

PBS-905Q

|

PBS-905O

|

|

Max. product capacity

|

C.C.

|

450~1,800

|

300~500

|

|

Min./Max. dia. of product

|

mm

|

50~120

|

30~60

|

|

Screw diameter

|

mm

|

90

|

90

|

|

Screw L/D ratio

|

|

24/1

|

24/1

|

|

Inverter motor

|

HP

|

60

|

15

|

|

Screw rotating speed

|

r.p.m.

|

15~65

|

15~65

|

|

Extruding capacity

|

kg/hr

|

130

|

130

|

|

Outer diameter of die mouth

|

mm

|

65

|

35

|

|

Mould center distance

|

mm

|

140

|

80

|

|

Clamping force

|

ton

|

16.8

|

16.8

|

|

Oil hydraulic drive motor

|

HP

|

30

|

30

|

|

Dry cycle

|

sec.

|

6.0

|

6.5

|

|

Pressure of air

|

Kg/cm²

|

6~8

|

6~8

|

|

Compressed air consumption

|

L/min

|

1,500

|

1,500

|

|

Total power consumption

|

kw/h

|

99.2

|

101.0

|

|

Machine net weight

|

kg

|

12,000

|

12,000

|

|

Gross weight

|

kg

|

13,000

|

13,000

|

|

Machine dimensions

|

m

|

5.3x2.5x2.4

|

5.3x2.5x2.4

|

*All specifications and designs are subject to change without notice.

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.