KM Model NO. PBS-905 (S / D / T / Q / O)

Video:

- Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

- Multiple die head configuration is especially ideal for producing medium and small sized containers at high production speed. Custom machine configurations are available.

- Also available to produce product with visi-stripe, two color and two layers.

- 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

Machine Specification

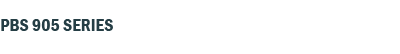

| NO. | Max. | Min. | A | B | C | D | E | F | G | H | I | J |

| PBS-905S,D | 640 | 240 | 450 | 65 | 50 | 220 | 60 | 220 | 449 | 18 | 220 | 165 |

| PBS-905Q | 500 | 200 | 630 | 55 | 50 | 420 | 60 | 200 | 429 | 18 | 310 | 150 |

| PBS-905O | 420 | 80 | 650 | 65 | 50 | 420 | 60 | 200 | 429 | 18 | 320 | 150 |

- For use with in-mold labeling machine. Open-close clamping mold is specified upon request.

Machine Specification

| Model No. | UNIT | PBS-905S | PBS-905D | PBS-905T | PBS-905Q | PBS-905O |

| Max. product capacity | C.C. | 10,000-20,000 | 1,500-5,000 | 600-2,700 | 450-1,800 | 300-500 |

| Min./Max. dia. of product | mm | 150-300 | 80-180 | 60-140 | 50-120 | 30-60 |

| Screw diameter | mm | 90 | 90 | 90 | 90 | 90 |

| Screw L/D ratio | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | |

| Inverter motor | HP | 60 | 60 | 60 | 60 | 60 |

| Screw rotating speed | r.p.m. | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 |

| Extruding capacity | kg/hr | 130 | 130 | 130 | 130 | 130 |

| Outer diameter of die mouth | mm | 240 | 135 | 80 | 65 | 35 |

| Mould center distance | mm | ~ | 250 | 160 | 140 | 80 |

| Clamping force | ton | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 |

| Oil hydraulic drive motor | HP | 30 | 30 | 30 | 30 | 30 |

| Dry cycle | sec. | 5.7 | 5.7 | 6.0 | 6.0 | 6.5 |

| Pressure of air | kg/cm2 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Compressed air consumption | L/min | 1,500 | 1,500 | 1,500 | 1,500 | 1,500 |

| Total power consumption | kw/h | 96.0 | 94.0 | 95.7 | 99.2 | 101.0 |

| Machine net weight | kg | 10,000 | 12,000 | 12,000 | 12,000 | 12,000 |

| Gross weight | kg | 11,500 | 13,000 | 13,000 | 13,000 | 13,000 |

| Machine dimensions | m | 5.6x4.4x3.5 | 5.1x3.1x2.9 | 5.1x3.1x2.9 | 5.3x2.5x2.4 | 5.3x2.5x2.4 |

*All specifications and designs are subject to change without notice.

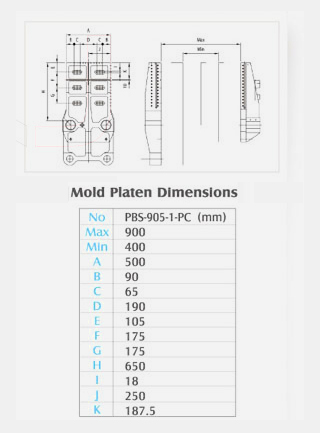

KM Model NO. PBS-505PC, PBS-605PC, PBS-705PC, PBS-905PC

Video:

Equipped with 10" TFT colorful LCD screen with human-machine interfacing control system. It provides powerful functions, maximum operational convenience and user-friendly operation. It also can be fitted with an imported Japanese MOOG 30point parison control to ensure consistent product quality and uniform thickness. Equipped with bottom-blowing device.Take-out robot can take out products automatically. It can increase production speed and efficiency greatly.

Machine Specification

| MODEL NO. | UNIT | PBS-905-1-PC |

| Product max. capacity | C.C. | 10,000-20,000 |

| Min./Max. dia. Of product | mm | 150-270 |

| Screw Diameter | mm | 95 |

| Screw L/D Ratio | L/D | 26/1 |

| Inverter Motor | HP | 75 |

| Capacitor for Barrel | KW | 17.35 |

| Screw Speed | r.p.m | 20-60 |

| Capacitor for Die Head | KW | 14.93 |

| Clamping Force | Ton | 20.8 |

| Hydraulic Drive Motor | HP | 40 |

| System Air Pressure | Kg/cm² | 6-8 |

| Air Consumption | L/min | 1,500 |

| Total Electric Power | KW | 125 |

| Average Energy Consumption | KW | 100 |

| Machine N.W. | Kg | 16000 |

| Machine G.W. | Kg | 16620 |

*All specifications and designs are subject to change without notice.