商品編號: PBSS-905 / 1005 (S / D / T / Q)

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency.

This series is designed to meet high production requirements. Available to equip with auto deflashing device and take-out robot to achieve fully automatic, highly efficient production.

Feature:

-

10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

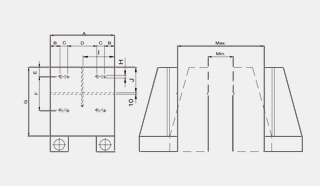

Mold Platen Dimensions

|

NO.

|

PBSS-905

|

PBSS-1005

|

|

MAX.

|

500

|

640

|

|

MIN.

|

160

|

240

|

|

A

|

380

|

420

|

|

B

|

50

|

65

|

|

C

|

50

|

50

|

|

D

|

180

|

190

|

|

E

|

60

|

60

|

|

F

|

196

|

220

|

|

G

|

415

|

449

|

|

H

|

1

|

18

|

|

I

|

185

|

205

|

|

J

|

150

|

165

|

*For use with in-mold labeling machine. Open-close clamping mold is specified upon request.

Principal Specifications

|

Model No.

|

UNIT

|

PBSS-605S

|

PBSS-605D

|

PBSS-605T

|

|

Product capacity

|

C.C.

|

1,000~5,000

|

600~2,700

|

200~1,000

|

|

Product diameter

|

mm

|

75~200

|

60~140

|

30~100

|

|

Screw diameter

|

mm

|

90

|

90

|

90

|

|

Screw L/D ratio

|

|

24/1

|

24/1

|

24/1

|

|

Inverter motor

|

HP

|

60

|

60

|

60

|

|

Screw rotating speed

|

r.p.m.

|

15~65

|

15~65

|

15~65

|

|

Extruding capacity

|

kg/hr

|

130

|

130

|

130

|

|

Max. Die mouth diameter

|

mm

|

150

|

80

|

50

|

|

Mould center distance

|

mm

|

~

|

160

|

120

|

|

Clamping force

|

ton

|

10.3

|

10.3

|

10.3

|

|

Hydraulic drive motor

|

HP

|

25

|

25

|

25

|

|

Dry cycle

|

sec.

|

4.8×2

|

4.8×2

|

5×2

|

|

Air pressure

|

bar

|

6~8

|

6~8

|

6~8

|

|

Air consumption

|

L/min

|

2,000

|

2,000

|

2,000

|

|

Total power consumption

|

kw/h

|

86.6

|

88.4

|

89.4

|

|

Machine net weight

|

kg

|

10,000

|

10,000

|

10,000

|

|

Gross weight

|

kg

|

12,000

|

12,000

|

12,000

|

|

Machine dimensions

|

m

|

4.6x4.4x2.8

|

4.6x4.4x2.8

|

4.6x4.5x2.8

|

|

Model No.

|

UNIT

|

PBSS-605Q

|

PBSS-705S

|

PBSS-705D

|

|

Product capacity

|

C.C.

|

50~500

|

2,500~10,000

|

1,500~5,000

|

|

Product diameter

|

mm

|

20~80

|

100~250

|

80~180

|

|

Screw diameter

|

mm

|

90

|

100

|

100

|

|

Screw L/D ratio

|

|

24/1

|

26/1

|

26/1

|

|

Inverter motor

|

HP

|

60

|

75

|

75

|

|

Screw rotating speed

|

r.p.m.

|

15~65

|

15~65

|

15~65

|

|

Extruding capacity

|

kg/hr

|

130

|

180

|

180

|

|

Max. Die mouth diameter

|

mm

|

40

|

200

|

135

|

|

Mould center distance

|

mm

|

100

|

~

|

250

|

|

Clamping force

|

ton

|

10.3

|

16.8

|

16.8

|

|

Hydraulic drive motor

|

HP

|

25

|

40

|

40

|

|

Dry cycle

|

sec.

|

5×2

|

5×2

|

5×2

|

|

Air pressure

|

bar

|

6~8

|

6~8

|

6~8

|

|

Air consumption

|

L/min

|

2,000

|

2,400

|

2,400

|

|

Total power consumption

|

kw/h

|

91.1

|

108.1

|

113.2

|

|

Machine net weight

|

kg

|

10,000

|

12,000

|

12,000

|

|

Gross weight

|

kg

|

12,000

|

13,500

|

13,500

|

|

Machine dimensions

|

m

|

4.8x4.5x2.8

|

5.3x6.2x3.2

|

5.3x6.2x3.2

|

|

Model No.

|

UNIT

|

PBSS-705T

|

PBSS-705Q

|

|

Product capacity

|

C.C.

|

600~2,700

|

200~1,000

|

|

Product diameter

|

mm

|

60~140

|

30~100

|

|

Screw diameter

|

mm

|

100

|

100

|

|

Screw L/D ratio

|

|

26/1

|

26/1

|

|

Inverter motor

|

HP

|

75

|

75

|

|

Screw rotating speed

|

r.p.m.

|

15~65

|

15~65

|

|

Extruding capacity

|

kg/hr

|

180

|

180

|

|

Max. Die mouth diameter

|

mm

|

80

|

50

|

|

Mould center distance

|

mm

|

160

|

120

|

|

Clamping force

|

ton

|

16.8

|

16.8

|

|

Hydraulic drive motor

|

HP

|

40

|

40

|

|

Dry cycle

|

sec.

|

5.2×2

|

5.2×2

|

|

Air pressure

|

bar

|

6~8

|

6~8

|

|

Air consumption

|

L/min

|

2,400

|

2,400

|

|

Total power consumption

|

kw/h

|

116.6

|

119.9

|

|

Machine net weight

|

kg

|

14,000

|

14,000

|

|

Gross weight

|

kg

|

15,500

|

15,500

|

|

Machine dimensions

|

m

|

5.6x6.2x3.2

|

5.6x6.2x3.2

|

*All specifications and designs are subject to change without notice.

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency.

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency.